In today’s industrial networking environments, choosing the right industrial router is critical to ensure reliable communication, efficient data transmission, and long-term stability. Unlike home routers, industrial routers must withstand extreme temperatures, vibrations, electro-magnetic interference, and support multiple device connections with high reliability.

In this guide, we’ll break down the key factors for selecting industrial routers — from decoding model numbers to matching real-world application needs — helping you make an informed choice.

Understanding Model Numbers: The Truth Behind AX, AC, and Speed Ratings

One of the first things you’ll notice when browsing routers are terms like AX3000 or AC1200. But what do they really mean?

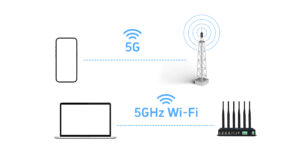

Wi-Fi 5 (AC) vs. Wi-Fi 6 (AX): Which is Better for Industrial Use?

- Wi-Fi 5 (802.11ac): Reliable but limited in handling multiple devices.

- Wi-Fi 6 (802.11ax): Designed for dense environments, supporting more devices with lower latency, thanks to technologies like OFDMA and MU-MIMO.

Example:

A factory floor with 50 AGVs (Automated Guided Vehicles) and 20 cameras found that upgrading from Wi-Fi 5 to Wi-Fi 6 reduced latency from 200ms to under 50ms, boosting productivity by 15%.

Tip: In harsh environments, expect Wi-Fi performance to drop by about 20% compared to lab specifications, especially at low temperatures.

Dual-Band vs. Tri-Band: How Many Bands Do You Really Need?

- Dual-Band (2.4GHz + 5GHz):

- 2.4GHz: Better penetration, suited for warehouses and tunnels.

- 5GHz: Faster speeds, ideal for real-time data like HD video.

- Tri-Band (2.4GHz + two 5GHz):

Perfect for wireless mesh networks — one 5GHz band can be used for device communication, and the other for a dedicated backhaul to avoid congestion.

Use Case:

A logistics warehouse uses dual-band routers to connect forklift terminals via 2.4GHz and transmit cargo images over 5GHz, maintaining packet loss rates below 0.5%.

WAN Connectivity: Wired or Wireless?

A good industrial router must handle different network access needs flexibly:

Wired WAN Interfaces

- Gigabit RJ45 Port:

- Cost-effective, easy to deploy, ideal for fixed installations (e.g., factories).

- Limitation: Distance under 100 meters.

- 10Gb SFP+ Fiber Port:

- Supports long-distance transmission (up to 20km).

- Resistant to electromagnetic interference — critical for wind farms, offshore facilities, etc.

Example:

A wind farm transmits vibration data 20km offshore via SFP+ fiber links, achieving <1ms delay and improving predictive maintenance accuracy by 30%.

Wireless WAN Interfaces

- 4G/5G SIM Card Slots:

- Ideal for mobile, remote, or backup communications.

- Look for models supporting multi-operator SIMs and VPN encryption (IPSec/OpenVPN).

- Satellite Communication (Optional):

- For extreme environments without terrestrial network coverage (e.g., polar stations).

Example:

An oil pipeline inspection vehicle uses a 5G WAN link for real-time video transmission, achieving 98% signal coverage and packet loss below 0.1%.

Protocol Support: Speaking the Same Language as Your Equipment

Industrial networks are full of diverse protocols — from Modbus RTU to EtherCAT. Your router should:

- Offer protocol conversion (e.g., Modbus to MQTT) to bridge old devices with modern cloud systems.

- Implement QoS (Quality of Service) to prioritize critical data like alarm signals and control commands.

Case Study:

A sewage plant prioritizes water quality data using QoS, ensuring real-time alarms without delay.

Durability Requirements: More Than Just a Rugged Shell

When it comes to industrial applications, reliability isn’t negotiable. Here’s what you should check:

EMC Certification

- Level 3:

Suitable for light industrial environments (e.g., textile, packaging). - Level 4:

Necessary for heavy interference areas (e.g., electroplating plants, substations).

Pro Tip: Don’t blindly pursue ultra-harsh certifications (e.g., EN 50121-4 for railways) if not necessary — it can increase costs without practical benefits.

Watchdog and Long-Term Stability

- Watchdog Mechanism:

Auto-reboots the router if the main controller crashes, ensuring 24/7 uptime. - MTBF > 100,000 hours:

Choose routers designed for continuous 5+ years of operation.

Conclusion: Matching the Right Router to Your Industrial Scenario

Choosing an industrial router isn’t just about specs — it’s about matching your needs for device density, communication stability, environment durability, and future scalability.

When selecting, always:

- Evaluate your environmental conditions (temperature, EMI levels).

- Consider device concurrency and data traffic needs.

- Plan for network redundancy with wireless WAN backup if needed.

- Ensure protocol compatibility for seamless system integration.

By understanding both the numbers behind the models and the demands of your real-world scenarios, you can select an industrial router that ensures long-term success and maximum operational efficiency.