2.4GHz vs 5.8GHz: Key Differences for Industrial Applications

When deploying wireless networks in industrial environments, choosing the right frequency—2.4GHz vs 5.8GHz—can make or break your operational efficiency. Let’s break down their strengths, limitations, and ideal use cases:

| Feature | 2.4GHz | 5.8GHz |

|---|---|---|

| Range | Longer range, better penetration | Shorter range, struggles with walls |

| Speed | Up to 600 Mbps (theoretical) | Up to 1300+ Mbps (theoretical) |

| Interference | High (common in crowded areas) | Low (less congested) |

| Best For | Wide-area coverage, legacy devices | High-speed, low-latency application |

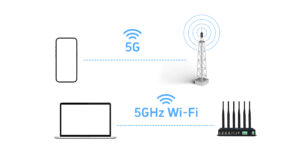

Why Industrial Networks Need Dual-Band Solutions

While 2.4GHz offers reliability over distance and 5.8GHz delivers speed, modern industrial IoT demands both. Here’s why dual-band industrial devices (like routers, access points, and serial servers) are critical:

1. Dual-Band Industrial Access Points

- Simultaneous connectivity: Run 2.4GHz for legacy sensors and 5.8GHz for HD video streaming or real-time data.

- Interference mitigation: Automatically switch bands to avoid congested channels in factories or warehouses.

- Future-proofing: Support newer 5.8GHz devices while maintaining backward compatibility.

2. Dual-Band Industrial Routers

- Mission-critical uptime: Use 5.8GHz for high-priority tasks (PLC communications) and 2.4GHz for backups.

- Seamless roaming: Devices stay connected while moving between zones (e.g., AGVs in smart factories).

3. Dual-Band Serial Servers

- Legacy-to-IP integration: Connect 2.4GHz serial devices (RS232/485) to modern 5.8GHz networks without rewiring.

- Low-latency data transfer: Prioritize 5.8GHz for time-sensitive industrial automation systems.

Real-World Applications of Dual-Band Industrial Devices

- Smart Manufacturing

- Use 5.8GHz for real-time machine monitoring and 2.4GHz for RFID tracking across large floors.

- Oil & Gas Remote Sites

- Deploy dual-band routers to handle video surveillance (5.8GHz) and environmental sensors (2.4GHz).

- Transportation Hubs

- Ensure uninterrupted passenger Wi-Fi (5.8GHz) and baggage handling systems (2.4GHz).

How to Choose Between 2.4GHz and 5.8GHz

Ask these questions before deploying your network:

- Do you need long-range coverage? → Prioritize 2.4GHz.

- Is low latency critical? → Opt for 5.8GHz.

- Is the environment RF-noisy? → Use 5.8GHz to avoid interference from Bluetooth/Wi-Fi devices.

Pro Tip: Dual-band industrial devices eliminate the need to choose—leverage both frequencies for optimized performance.

Why Our Dual-Band Industrial Solutions Stand Out

At Come-Star, we engineer rugged, dual-band devices designed for harsh environments:

1. Dual-Band Industrial Access Point

- Features: IP67 rating, -40°C to 75°C operation, MU-MIMO support.

- Use Case: Reliable connectivity in steel plants or outdoor solar farms.

2. Dual-Band Industrial Router

- Features: Dual SIM failover, VPN tunneling, and 5G readiness.

- Use Case: Remote SCADA systems requiring uninterrupted data flow.

3. Dual-Band Serial Server

- Features: RS232/485/422 support, AES-256 encryption, cloud management.

- Use Case: Modernizing legacy HVAC or conveyor belt systems.

FAQs: 2.4GHz vs 5.8GHz in Industrial Settings

Q1: Can 5.8GHz penetrate concrete walls in factories?

A: Poorly. Use 2.4GHz for thick walls or add mesh nodes with dual-band access points.

Q2: Is 2.4GHz secure enough for industrial IoT?

A: Pair it with WPA3 encryption and VLAN segmentation—standard in our dual-band routers.

Q3: Can I use both frequencies at the same time?

A: Yes! Our dual-band devices operate 2.4GHz and 5.8GHz simultaneously.

Conclusion: Future-Proof with Dual-Band Industrial Networks

The debate between 2.4GHz vs 5.8GHz isn’t about “either/or”—it’s about leveraging both to balance speed, range, and reliability. By deploying dual-band industrial routers, access points, and serial servers, you ensure seamless connectivity for today’s needs and tomorrow’s innovations.