Whether it’s coal in China, diamonds in Africa, gold in Australia, or nickel, copper, and rare earth minerals in Latin America and Canada, underground mining operations around the world share a common challenge: how to ensure safe, efficient, and intelligent operations in harsh, high-risk environments.

These operations take place in deep, often hazardous environments with extreme humidity, high temperatures, gas presence, dust, and electromagnetic interference. In such settings, reliable underground mining communication systems are essential—not only to keep workers safe but also to support automation, real-time monitoring, and data-driven decision-making.

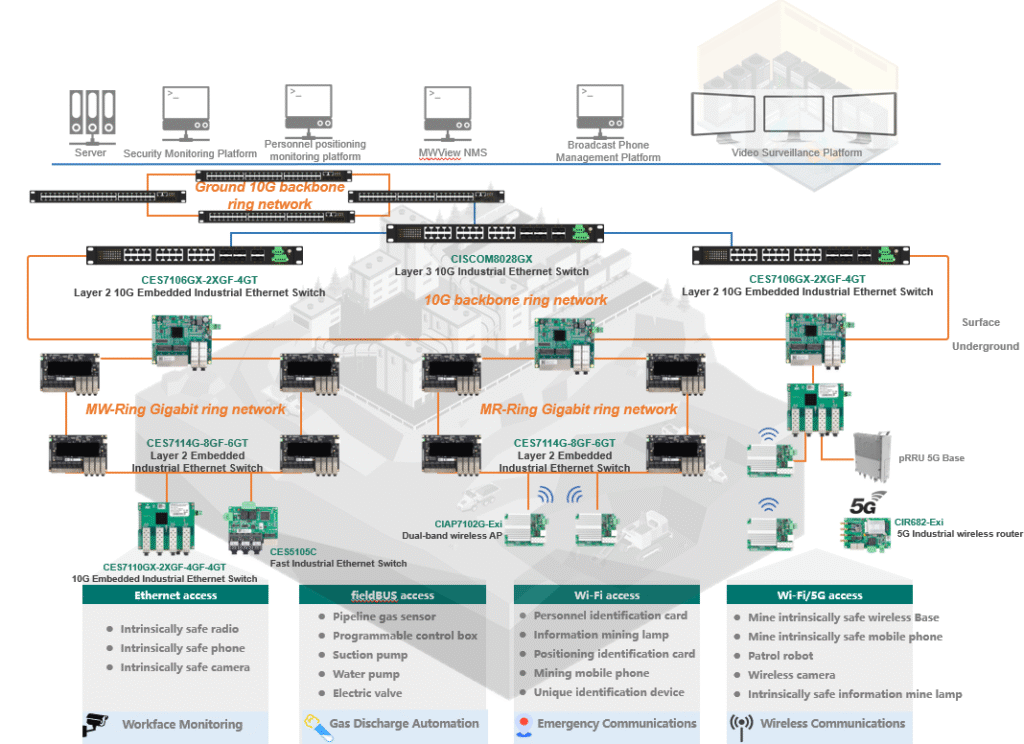

While the specific minerals may differ across regions, the communication requirements—low-latency transmission, environmental ruggedness, real-time visibility, and remote control—remain largely the same. That’s why the COME-STAR industrial-grade communication solution is designed to be adaptable across all types of underground mining operations, from coal to precious metals and industrial minerals.