Mit dem Besuch unserer Website stimmen Sie unserer Datenschutzerklärung in Bezug auf Cookies, Tracking-Statistiken usw. zu.

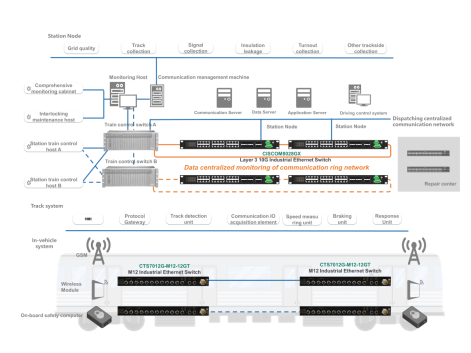

The integration of IoT in railways addresses the growing demand for safety-critical communications, broadband wireless connectivity, and predictive infrastructure management. Real-time monitoring, data analytics, and connected onboard systems are no longer futuristic—they are essential. From railway signaling and communications to onboard wireless networks, a stable and secure communication system is the backbone of smart railway infrastructure. Whether it’s a high-speed train, a regional rail line, or urban metro, uninterrupted connectivity ensures safety, efficiency, and passenger satisfaction.

Modern rail systems face mounting demands for efficiency, safety, automation, and real-time information. However, the complexity of railway environments presents multiple challenges:

Many rail infrastructures rely on outdated devices that aren’t IP-ready.

Railway operations cannot tolerate downtime or security breaches in mission-critical systems.

Extreme temperatures, vibrations, and electromagnetic interference make reliable communication difficult.

Onboard networks need to maintain stable connections while in motion.

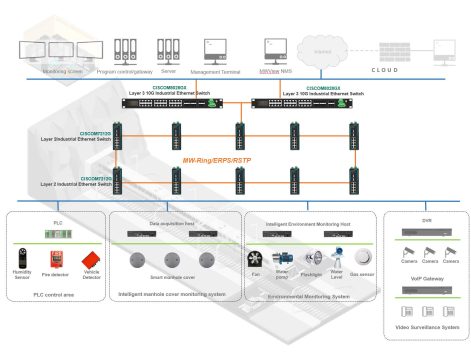

The railway industry is evolving through digital transformation, with IoT and edge connectivity at its core. Smart rail systems depend on secure and real-time communication to support safety-critical operations, operational monitoring, automation, and passenger experience. From Communications-Based Train Control (CBTC) to environmental monitoring in tunnels, IoT in rail is redefining how infrastructure and rolling stock perform and interact.

Real-Time Monitoring: IoT devices collect and transmit live data for improved responsiveness and predictive maintenance.

Scalability: Modular devices support gradual system expansion without full infrastructure replacement.

Enhanced Safety: Real-time environmental, diagnostic, and operational data improves decision-making and incident response.

Remote Accessibility: Cellular and wireless solutions enable centralized control over remote assets.

With the right industrial communication backbone, IoT transforms fragmented rail systems into smart, connected networks.

Railway networks span complex, distributed environments—each with unique operational needs. From the trackside and onboard systems to station infrastructure, deploying IoT technologies across these spaces enables seamless communication, enhances automation, and supports mission-critical applications. Below are the core areas where industrial communication devices bring value to modern rail systems.

Trackside environments require rugged, long-distance, and real-time communication solutions. These systems often operate in harsh outdoor conditions and demand high performance and high availability.

CBTC Systems: Real-time train control and position data communication

Trackside Sensor Networks: Vibration, axle load, and track integrity monitoring

Tunnel Environmental Monitoring: Airflow, gas, temperature, and humidity data collection

CCTV & Surveillance Backhaul: Video transmission from remote poles or enclosures

Trackside Cabinet Communication: Connectivity for signal relay and switch control systems

Inside the train, systems must handle constant motion, vibration, and intermittent connectivity. Devices onboard support both operational functions and passenger-facing systems.

Passenger Information System (PIS): Real-time updates, arrival time, media display

Surveillance & Monitoring: Onboard CCTV, data logging, remote streaming

Train Control & Diagnostics: Data exchange between carriages and central control

Vehicle-to-Ground Communication: Wireless uplink for live train status

Wi-Fi for Passengers: Internet access via cellular backhaul

Stations are complex hubs where operational efficiency and passenger experience converge. Connectivity supports automation, safety, and infrastructure integration.

Integrated Supervisory Control System (ISCS)

Building Automation Systems: Lighting, HVAC, energy monitoring

Automatische Fahrpreiserhebung (AFC)

Station Surveillance & Security

Public Wi-Fi Infrastructure

Our rugged networking devices are already powering rail sector at every stage. Tell us your deployment scenario — we’ll help you design a secure, always-on industrial IoT architecture.

To unlock the full potential of IoT in railway systems, you need rugged, reliable, and scalable connectivity — especially in remote and harsh environments. COME-STAR provides a complete portfolio of industrial communication hardware engineered for rugged and mission-critical rail applications:

Kontaktieren Sie uns noch heute für eine Kundenspezifische Lösung oder Angebot anfordern.

Unmanaged and managed DIN-rail or rack-mount switches, ideal for backbone and edge connectivity across all rail scenarios.

Ruggedized Ethernet switches with M12 connectors, built to withstand shocks, vibrations, extreme temperatures, and meet EN50155 railway standards—perfect for onboard and rolling stock applications.

4G/5G routers with VPN, dual SIM, and edge routing features for secure, mobile connectivity on the move or at remote stations.

Modbus, MQTT, and protocol-converting gateways to bridge OT and IT systems efficiently.

Enable RS232/485/422 devices to communicate over TCP/IP networks, maintaining legacy system value.

Long-distance data transmission over fiber for EMI-prone environments like tunnels and depots.

Reliable and compact cellular modems with industrial protocols, DIN-rail mounting, and rugged design.

Deliver Wi-Fi coverage onboard trains or in stations, with advanced roaming and redundancy.

Point-to-point and point-to-multipoint solutions for high-speed data transmission across long distances.

Join rail system integrators and OEMs who trust our communication hardware to keep critical data flowing — even in extreme conditions.

Für Standardprodukte: Normalerweise 1–2 Wochen (je nach Lagerverfügbarkeit).

Bei Sonderanfertigungen: 3–6 Wochen (je nach Komplexität).

Wir priorisieren dringende Bestellungen und sorgen für eine pünktliche Lieferung.

Ja, wir stellen Muster zur Evaluierung zur Verfügung. Kontaktieren Sie uns, um Muster anzufordern, und wir kümmern uns umgehend darum.

Um Partner zu werden, kontaktieren Sie uns einfach mit Ihren Geschäftsdaten und Anforderungen. Wir informieren Sie über die Partnerschaftsbedingungen, Preise und den Support, der Ihnen zum Erfolg verhilft.

Ja, wir versenden unsere Produkte weltweit. Wir arbeiten mit zuverlässigen Logistikpartnern zusammen, um eine schnelle und sichere Lieferung zu gewährleisten.

Schnelle Lieferzeit, max. 7 Tage

1.000 Einheiten in 2 Wochen fertig

50 Einheiten in nur 3 Tagen fertig

Über 200 maßgeschneiderte OEM-Lösungen

24 Jahre nachgewiesene Branchenexpertise

Bleiben Sie über die neuesten Produkte, Neuigkeiten und Lösungen auf dem Laufenden

Vielen Dank für Ihr Interesse an unseren Produkten. Bitte füllen Sie das untenstehende Formular aus. Wir antworten Ihnen innerhalb von 24 Stunden.